The intent of this article, prepared by members of an AWCI subcommittee on lath and plaster, is to provide information on model code language specific to the requirement of a drainage system or drainage material behind exterior cement plaster cladding. The text reflects the new language found in the model building codes. It does not reflect local amendments or interpretations that may be in place. If there are fire performance requirements such as ASTM E119, Standard Test Methods for Fire Tests of Building Construction and Materials; NFPA 285 Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components; or a locally enforced code, standard or statute, then the assembly must be built as fire tested. The contractor is advised to discern what is locally required for compliance and ascertain any fire-resistive requirements that must be met.

When will this change be required?

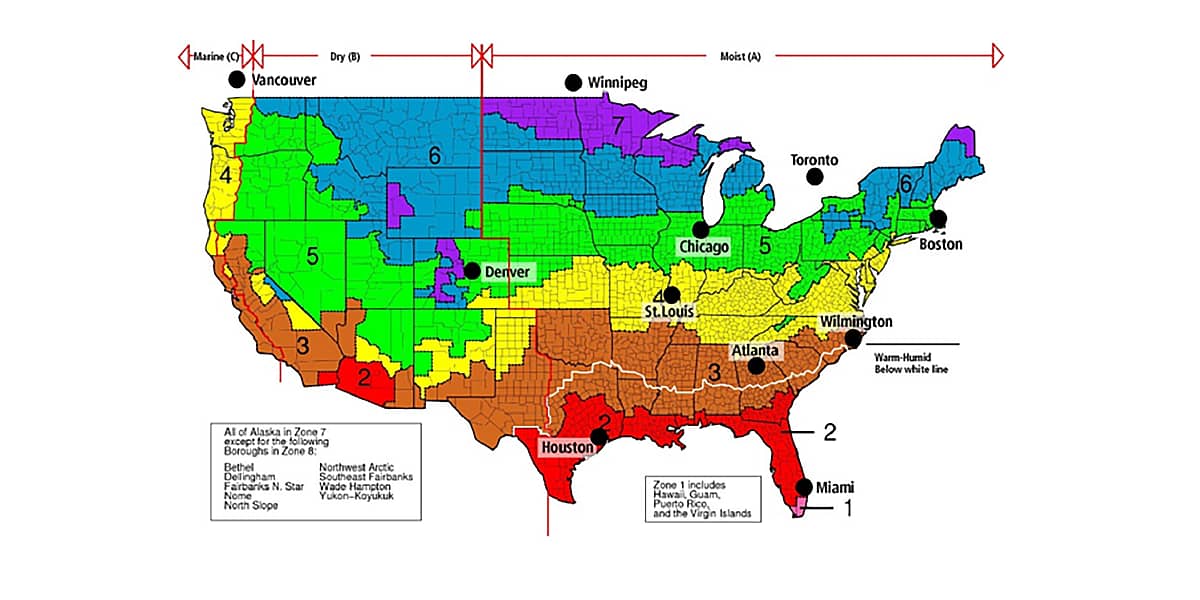

The International Code Council model building codes now include a requirement for a space or drainage material on exterior walls between cement plaster and a water-resistive barrier, WRB. This is mandatory when specific sheathings are used in certain geographic areas. Climate zone maps found within the model codes indicate where this is required.

The 2021 editions of the International Building Code and the International Residential Building Code include language that mandates either a space or a product called a drainage material be installed behind the cement plaster and in front of (on the exterior side of) the WRB in certain climate zones. The space is to provide a plane for drainage and ventilation. The 2021 code language is specific to only when wood-based sheathings such as plywood or oriented strand board are utilized under portland cement plaster on the exterior wall. This requirement affects projects located in what the codes consider either a moist or marine climate. The language in both the IBC and IRC is provided in the appendix of this document.

The code mandate for a WRB has existed for many years and is clearly defined in Chapter 25 of the IBC and Chapter 7 of the IRC. The WRB code language also can be found in the appendix to this document. The codes define multiple WRB options.

Based on recent code change activity, it is likely this space or drainage material requirement will be expanded to include any sheathing type.

Where will this change occur?

All new construction in Climate Zones A and C that are clad with wood-based sheathing and cement plaster must include a space for drainage or recognized drainage material. Wood-based sheathings include both plywood and OSB panels. The answer to where this applies in a geographical sense comes from a map contained within the International Energy Conservation Code that is referenced by the IRC and IBC. The map divides the United States into three broad climate zones: (A) Moist, (B) Dry and (C) Marine. A listing in Chapter 3 of the IECC also identifies all counties by zone for clarity.

The map above indicates that this new requirement should be enforced in the Pacific Northwest and essentially all states east of the Rocky Mountains. However, the Marine climate extends southward along the West Coast and includes parts of California. Hawaii falls under 1A or Moist. The blue arrows shown on the right are added to highlight the affected geographical locations.

Why is this change needed?

Changes in building materials and construction techniques coupled with the desire to reduce a structure’s operational energy has led to tighter controls being placed on water migration through the exterior envelope. The desire for tighter buildings has been evolving for decades. Reducing energy in the built environment is more recent, and stems from federal government initiatives.

What is changing?

The requirement for a WRB is not new. The first edition (2000) of the IBC called for a weather-resistive barrier behind cement plaster. The terminology has changed from weather to water, but the concept has remained constant: a second line of defense against liquid water attacking water sensitive sheathings and ultimately entering the stud cavity. Therefore, all cement plaster–clad buildings constructed to the IBC or IRC must incorporate a WRB. The 2021 edition of the IBC contains some significant changes regarding WRBs. Specific to wood-based sheathings, there are multiple options available to comply with the requirement for a WRB.

Two-layer WRB Options. The first option for the WRB consists of the application of two layers of 10-minute Grade D paper or two-layers of a WRB meeting ASTM E2556, Standard Specification for Vapor Permeable Flexible Sheet Water-Resistive Barriers Intended for Mechanical Attachment, Type I. Building papers are asphalt impregnated kraft papers that are classified by the weight of the paper itself. The heavier the paper and asphalt content, the greater the water resistance.

One-layer WRB Options. The codes do permit the use of a single-layer WRB. One choice is to install a 60-minute Grade D paper. As an alternative, a product with a water resistance equal to ASTM E2556, Standard Specification for Vapor Permeable Flexible Sheet Water-Resistive Barriers Intended for Mechanical Attachment, Type II, may be installed. In both instances, there also must be a non-water absorbing layer, such as foam sheathing, or a drainage plane (rainscreen or furring) installed between the plaster and the WRB.

With all WRB options it is imperative to install flashing at the appropriate locations as indicated in the code. For example, these locations include base of wall or head of window. Use of the ASTM E2556 option requires verification that the WRB material and application complies with the noted ASTM standard.

Drainage Space or Material in Climate Zones A or C. When wood-based sheathings are part of the exterior wall, both the IBC and IRC now require that either a supplemental space, or an approved drainage material shall be installed between the WRB and the plaster in Climate Zones A and C.

Both codes permit the space requirement to be satisfied by the incorporation of a minimum 3/16-inch space or gap between the WRB and the stucco. This space, sometimes referred to as a drainage plane, would allow for drainage of liquid water as well as provide ventilation. The space could be filled with a minimum 3/16-inch-thick drainage material to meet the requirement. The selected drainage material must be compliant to ASTM E2925, which is referenced below. A unique distinction to this requirement arises in climate zones that require continuous insulation. Here the placement of the space could be between the CI and the WRB, potentially placing the CI between the plaster and the drainage plane.

An additional option is when a single-layer WRB is installed with a drainage plane that complies with specific enhanced testing requirements. The supplemental tested requirements are identified in the code language.

There is no definition provided by the model codes on what constitutes a drainage material. One manufacturer succinctly interprets that a drainage material is “to facilitate the flow and drainage of incidental moisture from the wall assembly.”

Architectural specification and code experts suggest following a performance-based format in the selection of a drainage material. There are a couple of ASTM Standards that reference drainage materials and they are as follows:

-

ASTM E2925, Standard Specification for Manufactured Polymeric Drainage and Ventilation Materials Used to Provide a Rainscreen Function. -

ASTM E2273, Standard Test Method for Determining the Drainage Efficiency of Exterior Insulation and Finish Systems (EIFS) Clad Wall Assemblies.

In addition, ICC-ES Acceptance Criteria AC356 – Moisture Drainage Systems Used with Exterior Cement Plaster or Adhered Masonry Veneer Walls may provide a path for compliance. Use of materials or techniques described in an Evaluation Report or product listing compliant with AC 356 is subject to local jurisdiction approval.

Three types of drainage materials are available and listed in ASTM E2925, Section 4: entangled mesh materials, formed/textured sheet material and formed battens.

Want more articles like this? Subscribe to AWCI's Construction Dimensions for free now.

The drainage material selection should be clearly stated in the architectural specifications and referenced with the cladding being specified. The contractor should seek a product (and manufacturer) that can provide documentation that the proposed material will function as a drainage material and has been evaluated by a recognized laboratory. This includes being tested in accordance with the required standards. Each style has its own unique installation method, and the manufacturer’s installation instructions should be followed.

Appendix

Language from the International Building Code

The language shown is taken from the 2021 IBC. It is replicated in Section 703 of the International Residential Code with appropriate formatting modifications.

International Building Code 2510.6.1

Specific language on water-resistive barriers:

1. The water-resistive barrier shall be two layers of 10-minute Grade D paper or have a water resistance equal to or greater than two layers of water-resistive barrier complying with ASTM E2556, Type I. The individual layers shall be installed independently such that each layer provides a separate continuous plane and any flashing, installed in accordance with Section 1404.4 and intended to drain the water-resistive barrier, is directed between the layers.

2. The water-resistive barrier shall be 60-minute Grade D paper or have a water resistance equal to or greater than one layer of water-resistive barrier complying with ASTM E2556, Type II. The water-resistive barrier shall be separated from the stucco by a layer of foam plastic insulating sheathing or other nonwater absorbing layer, or a drainage space.

International Building Code 2510.6.2

In Moist (A) or Marine (C) climate zones, water-resistive barrier shall comply with one of the following:

1. In addition to complying with Item 1 or 2 of Section 2510.6.1, a space or drainage material not less than 3/16 inch in depth shall be applied to the exterior side of the water-resistive barrier.

2. In addition to complying with Item 2 of Section 2510.6.1, drainage on the exterior side of the water-resistive barrier shall have a minimum drainage efficiency of 90% as measured in accordance with ASTM E2273 or Annex A2 of ASTM E2925.

International Residential Code R703.7.3.2

R703.7.3.2 Moist or Marine climates.

In the Moist (A) or Marine (C) climate zones indicated in Figure N1101.7, water-resistive barriers shall comply with one of the following:

1. In addition to complying with Section 703.7.3.1, a space or drainage material not less than 3/16 inch (5 mm) in depth shall be added to the exterior side of the water-resistive barrier.

2. In addition to complying with Section 703.1.1, Item 2, drainage on the exterior of the water-resistive barrier shall have a drainage efficiency of not less than 90%, as measured in accordance with ASTM E2273 or Annex A2 of ASTM E2925.

For more information contact AWCI Director of Technical Services Robert Grupe at grupe@awci.org.