This growing company is destined for great success thanks to the experience of its founder.

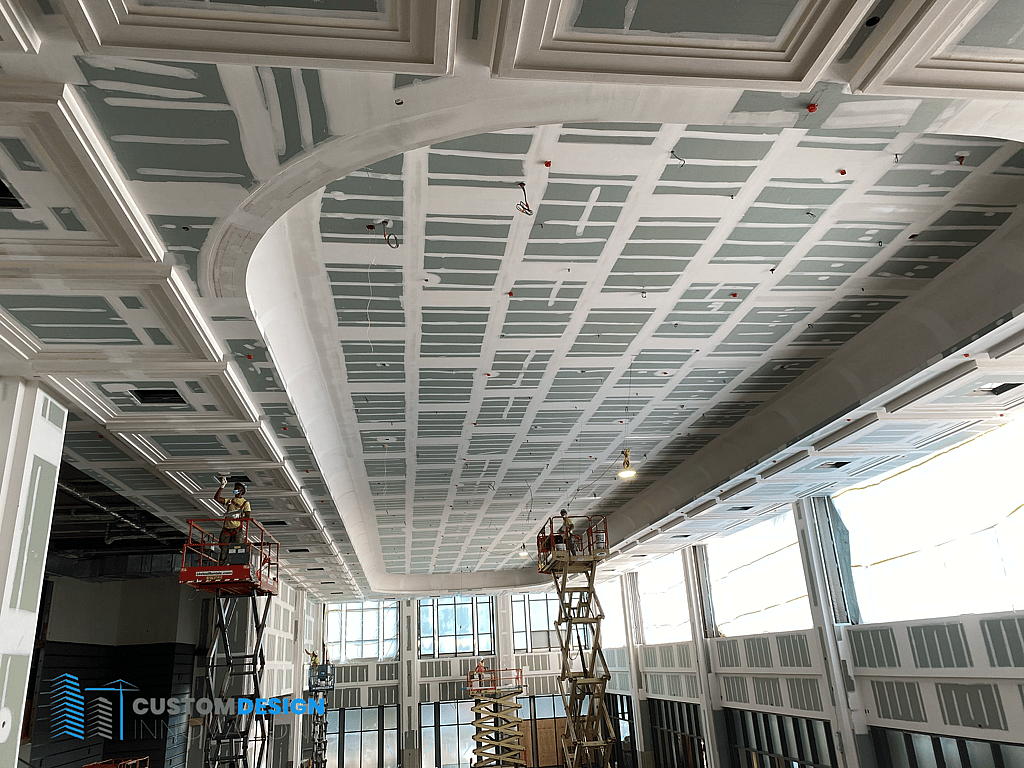

Photos used in this article were taken during the ceiling construction at the UBS Arena.

Staten Island’s Custom Design Innovations has come a long way in a short time. The self-performing, union certified minority business enterprise, which started in 2017 with three employees doing less than $300,000 in home renovations annually, today supports a staff of 50 to 120 and a business volume projected to be close to $15 million in 2024.

For Angel Marquez, the 42-year-old president and founder of the family-operated company, that quick rise stems partly from his experience in the field working as a union carpenter foreman for a drywall contractor, where over the course of 15 years he came to manage multimillion-dollar high-end commercial projects.

“I had been running large projects as a foreman so I knew how these jobs worked, and I had the ability to secure crews for big jobs through the union (Local 926 of the Carpenters union in Brooklyn, New York). I was very fortunate too that it was during COVID when a lot of jobs were shutting down and workers were available,” Marquez explains.

“By 2020 my company bid on a lot of large projects, mainly as a second-tier sub,” says Marquez, noting that year it subbed on the UBS Arena, home to the NHL’s New York Islanders, for custom ceiling, drywall and black iron services.

“I didn’t have much money to start but I told the contractor that I could do the job if they give me mobilization money up front so I could pay my insurance and start-up costs. They agreed and paid me biweekly,” he says.

Since then he has done about $10 million for that contractor for a full range of wall and ceiling services.

CDI closed that first year of the pandemic with 125 employees and $8 million revenue.

Extraordinary Ceilings—in the Bathroom

Custom ceiling work has factored into CDI’s jobs at New York City’s three major airports. As a primary sub, CDI is renovating 28 bathrooms over a three-year span for United Airlines at Terminal C at Newark Liberty International Airport. Not standard makeovers, the bathrooms are being gutted and refinished in high-end materials in strict adherence with architectural specifications. The ceilings are a textured tile product with quarter-inch reveals snapped in from the bottom up and tensioned in place.

“It is the type of ceiling that everybody said is way too advanced for bathrooms,” explains Marquez. “We have had a lot of challenges with them because each one has to be custom cut, and certain lights are specified with reveals around each tile.”

While CDI had done a similar ceiling at the UBS Arena, which was in a big, open space, “these tiles were not made for small applications,” Marquez says. “But the architect wouldn’t budge on the design, so we have a large quantity of tiles that have to be cut to size between the light fixtures. The ceiling even includes dummy lights to mimic two-by-four lighting. The architect wanted to make these bathrooms extraordinary.”

The tiles are precut by the manufacturer in at least two custom sizes per washroom, says John Furlong, project executive for CDI. “In the first bathroom we actually put up a cheap tile just to see if it was going to fit to confirm that the numbers we gave them would work.” A few tiles are cut on site to fit odd angles or perimeter bump-outs that are “touched up with paint” supplied by the tile manufacturer. Before installing the ceiling grid, CDI’s lathing foreman shoots all the pencil rod and black iron, required by code in New York City, and completes seismic bracing.

The Nightmare Begins

Working on three to four bathrooms at a time, CDI signed a base contract for $1.7 million with completion of the 28 bathrooms scheduled for two years, but delays in materials and production plus change orders have added up, leading to a 12-month contract extension and a hike in the original contract value.

“It was supposed to be a simple bathroom renovation,” Marquez says, “but the demolition contractor found things that weren’t accounted for such as rusted metal framing. We are reframing the whole space instead of just changing walls here and there.

“It is a contractor’s nightmare, and I didn’t account for all that (in the original contract) so I was expecting to lose on the project; however, through all these change orders we were able to make it up. I tell everybody it is only 28 bathrooms, but it has been our most challenging project.”

Airport Challenges

Furlong, who has been in the industry for 17 years, says surprises are inevitable on contracts at busy airports. “I think my biggest one at Newark was realizing the time required for clearance security.” It takes CDI’s crews about an hour to clear security protocols before they start working. “It comes down to planning and communication with the GC so you have the right stuff at the right time,” he says.

Working nights isn’t unusual because it is the optimum time for materials delivery, building temporary walls or going over punch lists. “If we run short on materials or supplies,” Furlong explains, “we have to drop them off early in the morning. If a delivery comes late, our workers have to leave the work area to go pick material from a late delivery or storage area, and they must be escorted by a TSA agent or the GC. That can mean delays up to an hour. It is time, and that costs us money.”

Furlong says CDI is restricted to only doing a few bathrooms at a time at the busy terminal. The GC has to get permission from the airline and the Port Authority on which bathrooms they can close.

Here, CDI’s scope of work includes the installation of a highly durable hygienic and antimicrobial premium PVC sheet panel associated with health care facilities in janitor closets at the terminal. It’s a tricky installation, says Furlong, because the panels are steam-bent around the room’s corners, and seams are welded with color-matched welding rods for a seamless finish with a heat gun designed for plastic welding and forming thermoplastics.

“It was a learning curve,” he says, adding that YouTube videos helped them understand the installation process and secure the right tools for the job.

New Products

CDI’s contract at United Terminal also includes drywall, doors and frames and a few specialty items. One such item is a high pressure laminate panel that is normally an exterior cladding, but here it is specified for the walls just outside the bathroom in the terminal’s concourse hall. It is the first time the contractor has worked with these panels.

“It was interesting in the beginning because you buy these panels bare, send them to a CNC fabricator in New Jersey to get the proper sizing based on field measurements and the architect’s specified reveals, and then buy clips from another company, install them and the rail system, and hang the panel” explains Marquez.

CDI has also been awarded a contract to install similar panels, except this one is an interior cladding product, at John F. Kennedy International’s Terminal 5 for JetBlue Airways. “We’re seeing these types of panels used more inside the three major airports in New York City, but a lot of contractors don’t have experience with them,” Marquez says.

Lessons to Learn

At JFK’s new Terminal One, CDI is in final negotiations with another AWCI member contractor for a metal ceiling package that includes expanded metal mesh panel and acoustical metal pan ceilings. The more than 100,000-square-foot project in the terminal’s main lobby includes black iron work. “One of the challenges for us is how the black iron, mesh panel and the metal pan will lay out and interact with the large suspended donut shaped light fixtures and any other MEP items up in the ceiling. In the end we have to make sure we demonstrate the ability to meet the design intent,” Furlong says, adding it will be the young contracting company’s biggest ceiling contract to date.

Among the challenges will be fabricating “an illuminated dome-shaped ceiling” integrated with large ring light fixtures. Issues include how to frame the ceiling and cut the panels, either in the field or by the manufacturer, to fit round light fixtures. Input on the renderings, the shop drawings for installation from the manufacturer and talking with the site super and the lather will help determine if extra rows of black iron are required to support the ceiling,” Furlong says. “We spend a lot of time discussing it, looking at it from angles, getting input in the field. We take that all into account for the price of labor in addition to the price of the metal ceiling.”

Marquez says estimating software doesn’t include the information on black iron u-channel carriers so they created their own spreadsheet and assemblies in the software to help with pricing by just entering some basic take-off quantities.

The contract is an example of a shift in New York where more metal ceiling systems are being specified at airports. “We want to get our guys trained so we can continue to bid on these jobs,” Furlong says.

While airport contracts are proving to be good business for CDI, the company lost money on a structural and ceiling support systems contract at LaGuardia Airport’s Terminal B during the pandemic when metal prices spiked 300% and lead delivery times extended.

What’s Next?

The company’s contracts in 2024 include renovations to a psychiatric ward, an animal hospital in Brooklyn, a substation at JFK and an OR renovation at a Brooklyn Hospital. At the mental health facility, CDI will be doing the carpentry, drywall, ceilings and millwork.

Marquez says workers will be using a new total station tool for layouts. “We give [the manufacturer] the drawings of the project with access points, they upload them onto the computer, and that will do the layouts for us. It points to the areas, my layout guy picks all the points and snaps the lines and it is done.”

Marquez expects it to cut labor by up to 50%. “Labor is 70% of our contract value, so any tool like this that can save us labor is a plus,” he says.

Marquez has also purchased cordless tools that track tool usage every time the batteries are charged. “It provides a log of what was done all day with the tool,” he says.

Also new for the contractor is facial recognition software that will help to determine where on site the contractor’s workers are and when they clock in and out. “I just bought a smart board and I bought iPads for the guys,” Marquez says. “I love technology and how it helps us interact with the clients and employees. It will help us grow.”

Indeed, growth is in CDI’s future. Any young company in this industry that survives a pandemic, new ceiling products that require learning new installation techniques, and lands high-profile projects in a tough New York market is destined for growth—and success.

Don Procter is a freelance writer in Ontario, Canada.