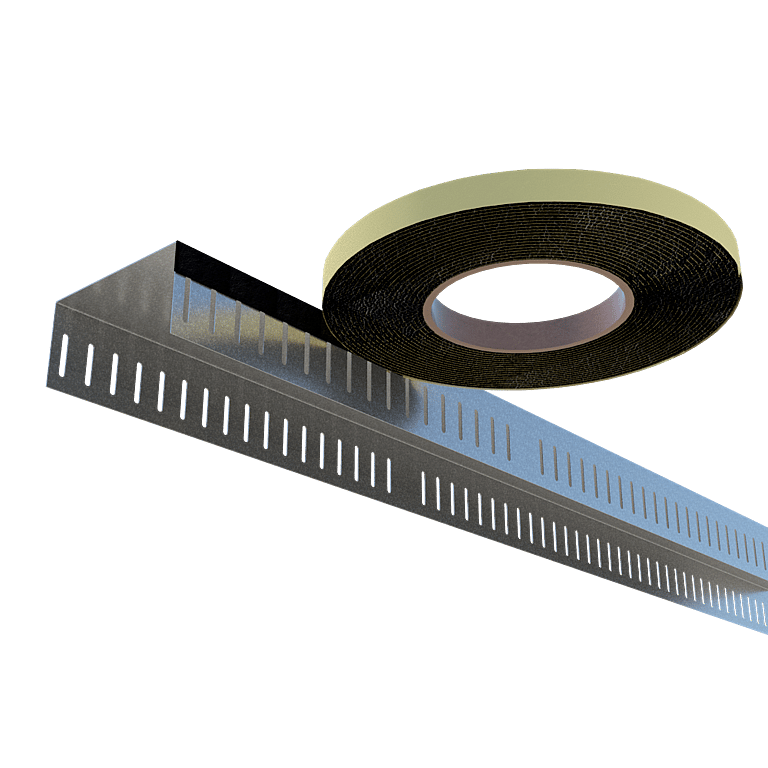

Simpson Strong-Tie has developed a new steel header hanger to support cold-formed steel framing box headers as well as large-flange lay-in headers used in curtainwall construction. The new SHH steel header hanger is engineered to ease installation by reducing drywall buildup, and screw count has been minimized with extensive component assembly testing.

Common in low- and mid-rise construction of multifamily and commercial building projects, cold-formed steel framing has emerged as a reliable and durable alternative to light-frame wood construction. The SHH steel header hanger is designed to transfer gravity and lateral loads from headers to the jamb studs and to help support the header assembly during installation.

In addition, the SHH steel header hanger has contractor-friendly geometry to reduce drywall buildup with a coped gusset to avoid the bottom track header legs. Extensive testing by Simpson Strong-Tie has enabled an array of available hole patterns to accommodate different load levels while minimizing installation costs and reducing screw count.

The SHH6 is manufactured in steel thicknesses of 54 mil (16 ga.) and 68 mil (14 ga.) and is intended for use with 6" (min.) box headers. The SHH3, manufactured from 68 mil (14 ga.) steel, is intended for 3 5/8" or 4" (max.) box headers and large-flange lay-in headers. Screw-hole layouts at the jamb studs accommodate flange sizes of 1 5/8", 2", 2 1/2", 3" and 3 1/2" in addition to built-up jamb configurations. All SHH steel header hangers feature a galvanized G90 finish.