There are several types of claddings that are available for use on exterior systems. They vary based on composition and all are engineered to meet in-place performance requirements. The two primary types are based on either a core of gypsum or that of concrete.

Note: The limitations provided here are taken from appropriate building product manufacturer’s source. For more and the latest information relative to these limitations, it is recommended to contact either the representative association or a specific building product manufacturer. A partial list of associations, and their links is provided on the home page of this site.

GYPSUM PANELS

GYPSUM WALLBOARD

Composition: non-combustible gypsum core with paper facings. Available in fire resistive Type X Core

Size: ½”. 5/8”, 4’ x 8’ – 14’, tapered edge

Application: Interior wall and ceilings

Compliance: ASTM C1396 Standard Specification of Gypsum Board

Limitations:

Avoid exposure to sustained temperatures exceeding 125 ˚F (52 ˚C).

Avoid exposure to excessive, repetitive or continuous moisture before, during and after installation. Eliminate sources of moisture immediately.

Non-loadbearing.

Fire-resistance ratings achieved when assembled in accordance with UL designs.

Installation: GA 216 Application and Finishing of Gypsum Panel Products

Architectural Spec: 09 21 16 Gypsum Board Assemblies

More and Latest Information Link: www.gypsum.org

FIBER REINFORCED GYPSUM BOARD

Composition: gypsum core with integral fiber reinforcing.

Size: ½”. 5/8”, 4’ x 8’, 10’, 12’, tapered edge

Application: Interior wall and tile base

Compliance: Per ASTM C 1278 Standard Specification for Fiber-Reinforced Gypsum Panel

Limitations:

Designed for interior use only.

For abuse-resistant or fire-resistant construction, 20-gauge or heavier studs are required.

Studs and joists must be in true alignment; bridging, firestops, etc. must not protrude beyond plane of framing. Due to strength and rigidity of panels, it may be difficult to compensate for out-of-plane imperfections in framing.

Installation: Manufacturer’s specification

Architectural Spec: 09 21 26 Gypsum Board Assemblies

More and Latest Information Link: manufacturer’s website

GLASS MAT WATER RESISTANT BACKING BOARD

Composition: non-combustible treated gypsum core with glass mat facer. Available in fire resistive Type X Core

Size: ½”,5/8”’ 4’ x 8’, square edge

Application: Tile Base

Compliance: ASTM C 1178 Standard Specification for Coated Glass Mat Water-Resistant Gypsum Backing Panel

Limitations:

Interior use only.

Always apply tile/finishes to the gray acrylic face.

Joints under tile should be set with alkali-resistant fiberglass mesh tape set in thin-set mortar or tile adhesive.

Conventional paper drywall tape, joint compound, drywall nails, and drywall screws should not be used in wet areas.

Not for use on floor installations.

Not recommended for use in shower pans or shower curbs.

Not a nail base.

Should not be exposed to temperatures exceeding 125°F (52°C).

Continuous exposure to extreme conditions in applications such as saunas, commercial steam rooms.

Do not install a vapor barrier directly behind tiled Tile Backer.

Do not apply tile backer directly to concrete or masonry block.

Fixture/plumbing penetrations and abutments to dissimilar materials should be caulked and sealed.

Maximum framing spacing – 24 inches on center (1/2″ or 5/8″ panel)

Installation: Manufacturer’s Specs

Architectural Spec: 09 28 16 Glass Mat faced Gypsum Backing Boards

More and Latest Information Link: www.gypsum.org

GYPSUM LATH

Composition: non-combustible gypsum core with paper face.

Size: 3/8” x 24” x 8’ rounded edge

Application: Base for gypsum plaster

Compliance: ASTM C 1396 Standard Specification of Gypsum Board

Limitations:

Avoid exposure to temperatures exceeding 125 °F (52 °C)

Avoid exposure to excessive or continuous moisture before, during and after installation. Eliminate sources of moisture immediately Panels require weather-protected storage

Non-load bearing.

Do not use with veneer plaster products.

Do not use gauged lime putty finish or portland cement plaster, as bond is inadequate.

Do not use as a base for ceramic tile.

Installation: ASTM C 841 Standard Specification for Installation of Interior Lathing and Furring

Architectural Spec: 09 21 13 Plaster Assemblies

More and Latest Information Link: www.gypsum.org

GYPSUM PLASTER BASE

Composition: non-combustible gypsum core with paper face.

Size: 1/2”, 5/8” x 4’ x 8’ – 14’

Application: Base for veneer plaster

Manufactured: Per ASTM C 1396 Standard Specification of Gypsum Board

Limitations:

Gypsum bases should only be used with veneer plaster products.

Gypsum bases should not be used in areas exposed to excessive moisture for extended periods or as a base for

adhesive application of ceramic tile

Do not apply any lime containing finish plaster to gypsum base that has faded from exposure to sunlight. Where fading contact panel manufacturer for resolution.

Avoid exposure to temperatures exceeding 125 °F (52 °C)

Avoid exposure to excessive or continuous moisture before, during and after installation. Eliminate sources of moisture immediately Panels require weather-protected storage.

Installation: Per ASTM C 844 Standard Specification for Application of Gypsum Base to Receive Gypsum Veneer Plaster

Architectural Spec: 09 21 13 Plaster Assemblies

More Information Link: www.gypsum.org

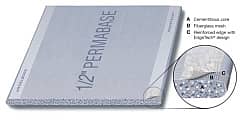

CEMENT PANELS

Composition: aggregated Portland cement core reinforced with a polymer-coated glass fiber mesh

Size: ½”, 5/8”, 32”, 36”, 48” x 5’, 8’, round edge

Application: Tile Base

Compliance: ASTM C 1325 Standard Specification for Non-Asbestos Fiber-Mat Reinforced Cementitious Backer Units

Limitations:

Max. stud spacing 16 inches on center.

20 ga. (30 mil) cold-formed steel framing minimum.

Do not use drywall screws or joint tape.

Non-load bearing.

Installation: Manufacturer’s Specs

Architectural Spec: 09 28 13 Cementitious Backing Boards

More Information Latest Link: Manufacturer’s website

Information contained herein is obtained from the following sources:

The Gypsum Association, www.gypsum.org

National Gypsum Company, www.nationalgypsum.com

United States Gypsum Company, www.usg.com

While reasonable effort has been made to ensure the accuracy of this information, we assume no liability for any errors or omissions on these pages. Please verify all information with the organizations mentioned above.